Test dusts

All dusts are not alike! Chemical compositions, particle size distributions, morphologies, densities and other characteristics differ depending on the dusting materials, the process of dust generation and the environmental conditions. Using test dusts as reference materials, lab staff simulate, as exactly and comprehensively as possible, the dust exposure of products in real-life situations.

Depending on whether the performance of a vacuum cleaner filter or gas turbine filter is being measured or whether the dust resistance of technical components has to be tested, the test dust being used must always have the same properties as the dust which the test specimen has to withstand in the real-life situation. Among the best-known test dusts are, for example, ASHRAE 52.2 test dust, which was used in EN 779, and Arizona test dusts, which are used in many normative filter tests.

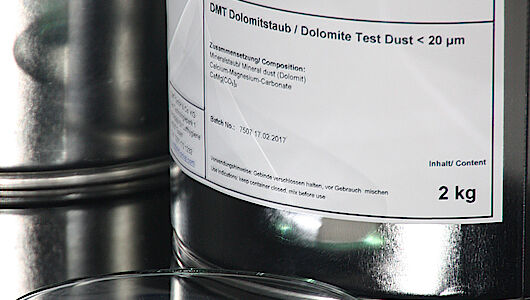

DMT manufactures test dusts to a large variety of specifications for filter tests or environmental tests. The dusts comply with the relevant standards (standard test dust) and meet individual customer requirements (test dust). The specifications, the high quality control of the raw materials and the resulting test dust ensure highest quality. Thereby the physical behaviours such as dust-cake formation or the tendency of the dust to clog is reproducible from test to test and batch to batch.

Test dusts in compliance with international standards

Due to increasing awareness of the noxious effect of fine dust, the norms relating to air filter media and test procedures for air filter products have become more stringent.

This is reflected in the increasing number of test standards in the field of air filtration. These standards govern the procedures for measuring and evaluating the performance of filter products and the materials to be used in these procedures. Through compliance with these standards, independent laboratories are able to achieve test results that are reproducible and comparable worldwide. Depending on the use to which they are put, machines, consumer products and electronic or optical components must be dust-proof and dust resistant.

These applications, too, are subject to a wide range of test norms. Test dusts with precisely defined properties are instrumental in the achievement of reproducible test results. We supply the reference material that you need.

High manufacturing standards

The more precise the specification of a test dust is, the more reproducible and comparable the test results are. Filter testing in particular is subject to narrow tolerance ranges concerning composition and particle size distribution of the dust. The utmost care must therefore be taken when selecting and processing raw materials.

Minerals like quartz, alumina, or calcium oxide, salts and organic fibres like cotton or cellulose are the main components of test dust and dust mixtures for filter tests.

With minerals, the particle size distribution is adjusted by milling and fractionation processes. Fibrous materials are cut to the required length. Extensive interior and exterior quality checking of raw materials and intermediate and final products takes place at various stages of the dust manufacturing process. The result is professionally manufactured products that are able to deliver reliable and trustworthy test results.

Customized test dusts

Do you need a test dust with specific properties, with particularly abrasive particles or specific size distributions or made of certain materials, for instance? We produce your test dust according to your specifications, in small or large quantities. Please contact us to discuss your requirements.

If you wish, you can also play a part in our research and development by allowing us to be involved in your own tests and projects. Other dusts are available on demand and we produce test dusts to suit customer requirements.

IEC 62885 (2016): Surface cleaning appliances

IEC 60312 (2010): Vacuum cleaner for household use

EN 60312 (2017): Vacuum cleaner for household use

For the testing of surface cleaning equipment, the IEC Technical Subcommittee (IEC 59F) has decided to establish a collection of tests, test equipment and test materials (e.g. test dusts). Existing standards and annexes such as IEC 60312 (2010) will therefore be integrated into IEC 62885 (2016). The DIN EN 60312 (2017) standard at European and German level will continue to apply. Despite the change in the structure, the numbering of the chapters in all of the above standards has remained largely the same, making the contents easier to find again.

The DMT GmbH & Co. KG, Air Quality Product Testing Department, Test Dust Division, is an active member of various working groups of IEC Subcommittee 59F and a guest at DKE/UK 513.7 and is involved in the development of technical specifications as a manufacturer of test material/test dust.

The following test dusts of these standards are produced by DMT GmbH & Co. KG and distributed:

DMT Dolomite sand according to IEC 62885 / IEC 60312 / DIN EN 60312 7.2.2.1

DMT Carpet sand according to IEC 62885 / IEC 60312 / DIN EN 60312 7.2.2.2

DMT Test dust type 8 acc. to IEC 62885 / IEC 60312 / DIN EN 60312 7.2.2.3

DMT Mineral sand Type 3 acc. to IEC 62885 / IEC 60312 / DIN EN 60312 7.2.2.4

DMT Emission test dust acc. to IEC 62885 / IEC 60312 / DIN EN 60312 7.2.2.5

DMT Cellulose powder according to IEC 62885 / IEC 60312 / DIN EN 60312 7.2.2.6

DMT plastic granules according to IEC 62885 / IEC 60312 / DIN EN 60312 7.2.5

ISO 12103-1 (2010): Road vehicles - Test contaminants for filter evaluation

Arizona test dusts, defined in ISO 12103-1, are among the oldest test dusts. This standard defines both the particle size distribution and the chemical composition.

The following test dusts are produced by DMT GmbH & Co. KG and distributed:

DMT Arizona test dust A1 ultrafine epsd acc. to ISO 12103-1

DMT Arizona test dust A2 fine acc. to epsd ISO 12103-1

DMT Arizona test dust A3 medium epsd acc. to ISO 12103-1

DMT Arizona test dust A4 coarse epsd acc. to ISO 12103-1

The DMT Arizona test dusts comply to the specified particle size distribution of the ISO 12103-1 standard, but they consist 98% of quartz, which give the test dusts an additional identification "epsd". "epsd" stands for "equivalent particle size distribution".

IEC 60068-2-68: Environmental testing Part 2-68: Test - Test L: Dust and Sand

This standard specifies test methods and test dusts to determine the influence of sand and dust on electro technical products.

The following test dusts described in this standard are available at DMT GmbH & Co. KG :

Talcum < 75 µm, test La

Quartz dust < 75 µm, test Lb

Quartz sand < 150 µm, test Lc1 and Lc2

Quartz sand < 850 µm, test Lc1 and Lc2

ARAMCO 32-SAMSS 008: Aramco Test Dust

DIN EN 60335-2-69: Mineral dust acc. to Annex AA

ASTM F 608 A1: Mineral dust Talcum

ECE R45: Test Dirt / Test Mud acc. to Annex 4 2.1.1.

ECE R45: Test Dirt / Test Mud acc. to Annex 4 2.1.2.

CEN ISO 679: Quartz dust

DIN 196: Quartz dust

ISO 11057, VDI 3926-1, ASTM D6830: Pural NF

DIN EN 779: ASHRAE Test Dust acc . to Standard 52.2