Particle and Fiber Analysis

In our laboratories, various characteristic properties of particles and fibers are determined. These include dusting behavior, particle size and fiber length distribution, bulk and specific density, as well as the surface size of the material.

In order to reduce the exposure of workplaces to dust as well as environmental impact from dust emissions, key figures on dusting behavior (common synonyms: dustiness, propensity to dust, dust emission) are helpful and therefore valuable information.

DMT offers services for particle and fiber analysis, which include the following:

- Examination of dusting behavior using methods with a rotating drum (DIN EN 15051-2 or DIN 55992-1) and optionally the determination of the inhalable, thoracic, and respirable dust fractions according to DIN 481 using DMT-modified Heubach method 2.

- Determination of particle size distributions via sieving (DIN 66165-2), laser diffraction (ISO 13320), or microscopic image analysis (BS 3406-4).

- Determination of fiber length distributions (ISO 22314).

- Determination of specific surface area (BET analysis).

- Moisture determination (IR dryer).

- Determination of the specific density of bulk materials using helium pycnometry.

For more information, please contact us at tel:+492011721232 or via email at plq(at)dmt-group.com.

Examination of dusting behavior using methods with a rotating drum

(DIN EN 15051-2; DIN 55992-1 and in the modified Heubach method 2)

Determination of the inhalable, thoracic, and respirable dust fractions according to DIN 481

DMT conducts investigations of dusting indicators using three variants with a rotating drum. The basic structure and processes are analogous in all three methods. A sample of the bulk material is set in motion within a drum of diameter d and at a rotational speed of n for a defined time t using entrainment plates. Airborne particles from the cascading bulk material are discharged from the drum by an axial imposed air flow V̇. The discharged particles are quantified in the subsequent analysis, and optionally, the particle fractions are determined. The process parameters d, n, t, and V̇ are specified in the respective standards and are specific to the standard, as is the particular analysis method.

Contact

Kontakt

Dr. Dirk Renschen

Telefon: +49 201 172-1304

Telefax: +49 201 172-1606

E-Mail: gs(at)dmt-group.com

Services

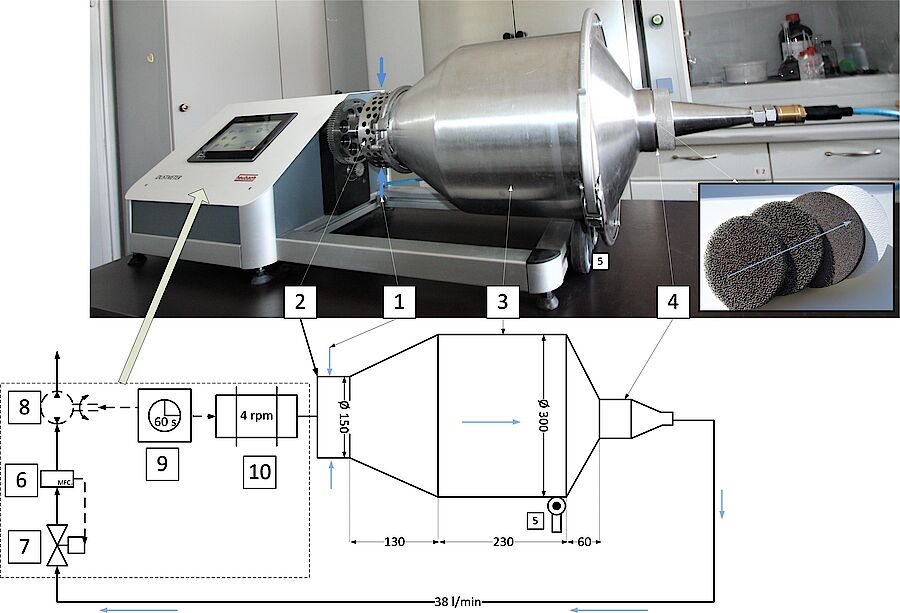

DIN EN 15051-2 Workplace exposure - Measurement of the dusting behavior of bulk materials

| d = 30 cm | n = 4 min-1 |

| t = 60 s | V̇ = 38 l/min |

Initially, 35 cm3 of sample is used. The discharged particles are collected using three particle size-selective metal foams and an absolute filter. The first two metal foams are identical. The duplication is normatively anchored and serves the purpose of manageability. Within this standard, the following table can be found for classifying the obtained results.

| Classes: | very low | low | moderate | high |

| Dustiness of inhalable dust, wI,A mg kg-1 | < 300 | 300 to 650 | > 650 to 3000 | > 3000 |

| Dustiness of thoracic dust, wT,A mg kg-1 | < 80 | 80 to 300 | > 300 to 1000 | > 1000 |

| Dustiness of respirable dust, wR,A mg kg-1 | < 10 | 10 to 60 | > 60 to 210 | > 210 |

Figure 1: Basis for evaluating the results. Taken from DIN EN 15051-2

Legend:

- Air flow

- Inlet unit (protective filter)

- Dust generation unit - rotating drum

- Outlet unit / sampling system (two particle size-selective filter foams and an absolute filter)

- Roller

- Inline mass flow meter

- Control valve

- Vacuum pump

- Timer

- Drive motor

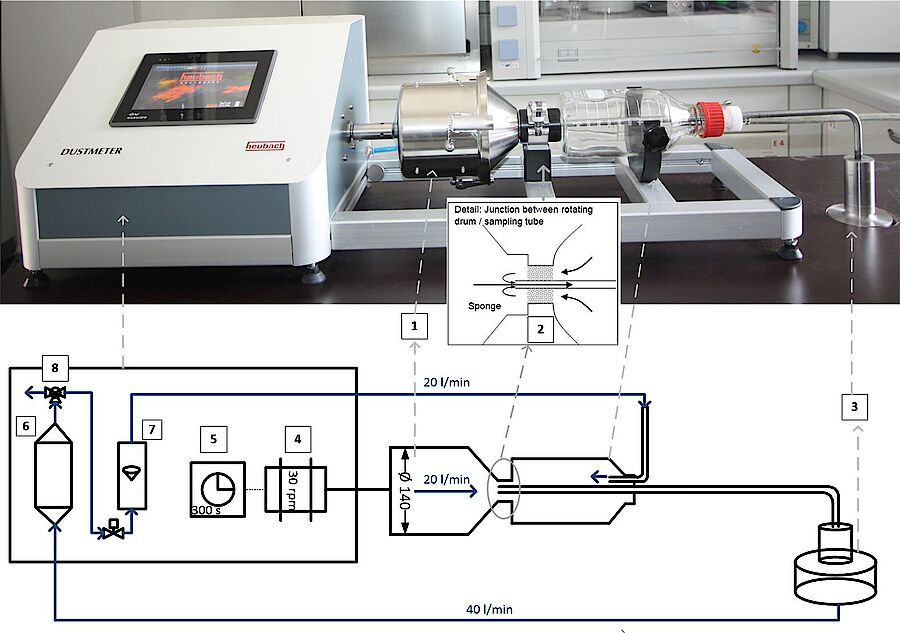

DIN 55992-1 Determination of a measure for the dusting tendency of pigments and fillers - Part 1: Rotational method

| d = 14 cm | n = 30 min-1 |

| t = 300 s | V̇ = 20 l/min |

The discharged laden air flow passes through a horizontally oriented glass section, which fundamentally serves as a coarse separator or sifter. Subsequently, the finer particles are collected on an absolute filter and quantified gravimetrically. This results in a dimensionless parameter that relates the collected dust quantity on the filter to the initially used 100 g sample quantity.

DMT Modified Heubach Method 2 as a variant of DIN 55992-1

| d = 14 cm | n = 30 min-1 |

| t = 300 s | V̇Trommel = 20 l/min |

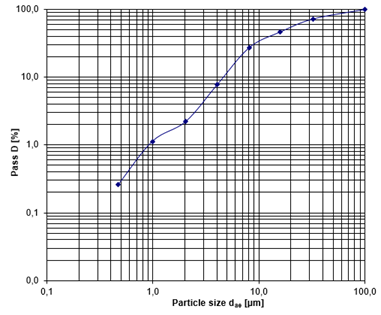

The discharged laden air flow is directed through a probe into a seven-stage cascade impactor. A continuous curve is numerically generated from the particle size data points obtained, representing the particle size distribution of the aerodynamic diameter of the airborne particles.

Legend:

- Dust generation unit

- Detail: Sampling current + bypass current to obtain 40 l/min in total for (3)

- Seven stage cascade impactor

- Motor (30 rpm)

- Timer (300 s – 5 min)

- Vacuum pump

- Rotameter

- Three-way-valve

Laser Diffraction (ISO 13320)

Laser diffraction is the most commonly used method for determining particle sizes. It is capable of covering very large measurement ranges, from the nanoscale range to several millimeters.

With our Fritsch Analysette 22 laser diffractometer, we can measure particles in both dry and wet dispersion. During wet dispersion, weak interactions between individual particles are overcome, allowing artifacts caused by agglomerates to be overcome.

The measurement results in a particle size distribution of equivalent diameters for particles with spherical geometry. Regular independent calibrations by the manufacturer ensure the reproducibility of the recorded measurements.

The fundamentals of these methods are based on the following standards:

- DIN EN 15051-2 Workplace exposure - Measurement of the dusting behaviour of bulk materials - Part 2: Method using a rotating drum

- DIN 55992-1 Determination of a measure for the dusting tendency of pigments and fillers - Part 1: Rotational method (Heubach method)

- DIN EN 481 Workplace atmospheres; Size fraction definitions for measurement of airborne particles

- ISO 13320 Particle size analysis — Laser diffraction methods; DIN 66165-1 Particle size analysis - Sieving method - Part 2: Procedure

- DIN EN ISO 8130-13 Powder coatings - Particle size analysis by laser diffraction

- BS 3406-4 Determination of particle size. Microscopic examination and image analysis

- ISO 22314 Plastics - Glass fibre reinforced products - Determination of fibre length, ISO 16065-2:2014-01 Pulps - Determination of fibre length by automated optical analysis - Part 2: Unpolarized light method

- DIN ISO 9277 Determination of the specific surface area of solids by gas adsorption - BET method

- DIN 18121-2 Subsoil, Examination of soil samples - Water content - Part 2: Determination by rapid methods