Emergency Number: +49 231 5333-237

Special Firefighting

Where inflammatory or even spontaneously inflammable substances are stored, the risk of fire is particularly high. A further complicating factor is that fires are often caused by self-igniting processes in an undetected way. A detailed assessment of the fire occurrence is then hardly possible from the outside. In addition, there may be a risk of sudden throughputs or explosions. The necessary fire-fighting work requires a great deal of experience and considerable time and money. Here we can help you with our decades of experience in the field of special combustion (landfill, Haldenbrand, Silobrand and Bunkerbrand).

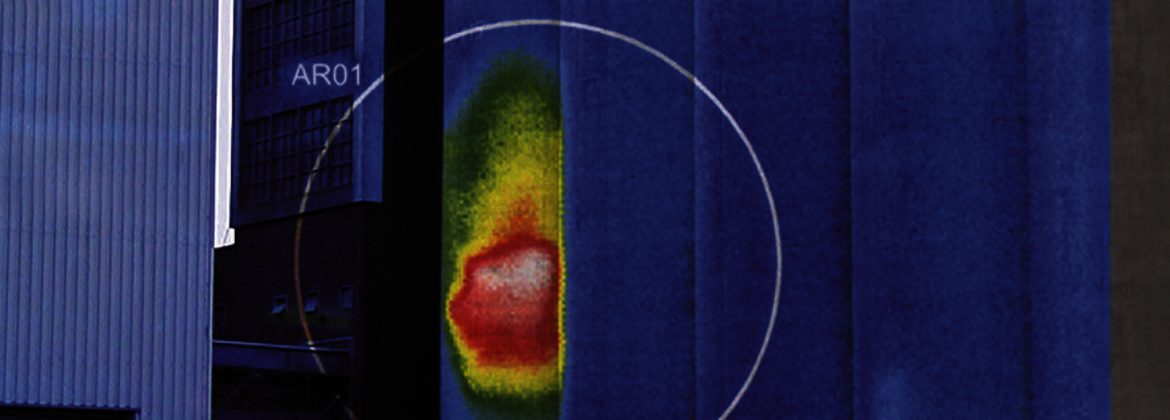

Silobrains require fire-fighting measures, in which even large professional firefighters require expert support. One of the reasons for this is that the fire brigade is partly lacking in the experience of combating such special fires, mostly with the use of nitrogen. Often there is also a lack of necessary measuring equipment such as high-resolution infrared cameras, high-precision carbon monoxide and oxygen measuring devices.

If we have found the brand, we will support you and, if necessary, the local fire brigade - with a view to possible explosions or penetrations - in the often very dangerous fire fighting.

On the basis of the results obtained, we can get an accurate picture of the location and extent of the fire. In addition, we have powerful fire-gas measurement technology to directly assess the intensity of the fire incident and to act accordingly.

After the deletion, we remain on the spot for the necessary period of time if necessary, in order to rule out a re-ignition. Only when there is no longer any danger will our order be fulfilled.

The method of inerting has proven to be successful in the control of coal and silo fractions. The required oxygen is withdrawn from the fire by supplying nitrogen or carbon dioxide and the fire extinguishes. At the same time, the risk of a breakdown or explosion is effectively reduced. In the event of a fire, the inert gas is supplied by a gas supplier within a short time. In order to provide large quantities of inert gas, for example nitrogen, as well as the complex technical equipment such as evaporators and corresponding safety devices in the shortest possible time, DMT GmbH Co. KG and the power supply company Westfalen AG have concluded a cooperation agreement. This includes a whole package of joint services for fire protection for silo plants. By means of our gas and temperature measurement technology, we ensure optimal control of the inerting measures and thus ensure a rapid and lasting erasure success.

Inertisation systems can also be installed as part of a holistic protection concept as a preventive measure. In accordance with the local conditions, we plan the appropriate plants for you or, if desired, check existing plants for a test float. In this connection, it is also determined whether all requirements are met with regard to health and safety at work during the operation of the inerting system.

Contact

Dipl.-Ing. Jörg Kayser

Publicly appointed and sworn expert for the fire protection of mines, coal deposits and landfills

Tel +49 231 5333-234

Fax +49 231 5333-299

<link mail-link>joerg.kayser@dmt-group.com

Seminar Fire and explosion protection for silos, bunkers, landfill sites

In our practice-oriented training courses, we prepare beginners and advanced users for the correct behavior in the event of a fire with regard to fire and explosion protection for silos, bunkers, landfill sites.