Tests according to DIN EN 45545

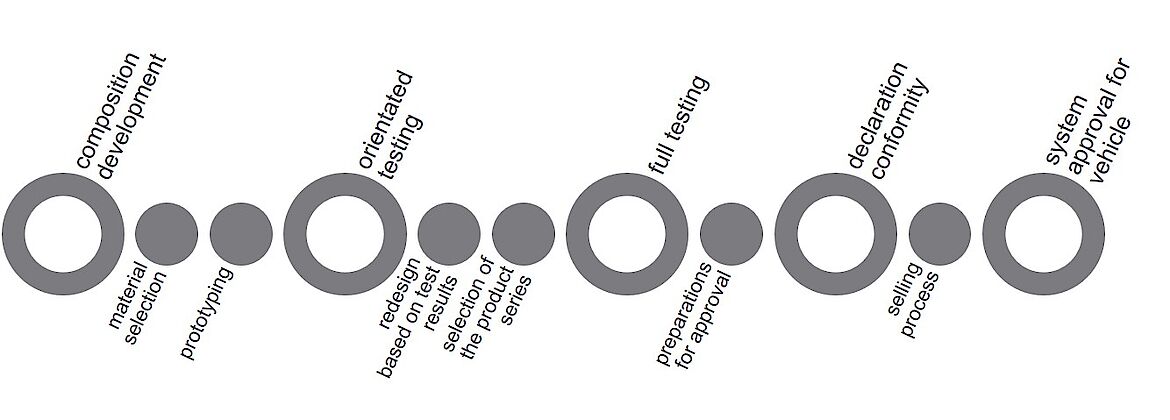

The European Standard EN 45545 is divided into 7 parts.

Protective Goal:

Rolling stock shall be designed such that it protects passengers and on-board staff in case of hazard fire on board and to allow an effective evacuation and rescue in case of emergencies.

TSI LOC&PAS (1302/2014/EU), section 4.2.10.1 (2)

Requirements for Testing as Key to European Market

- Application of trains and passenger carrigages on the trans-European rail system network (TEN) (high-speed and conventional rail)

- Requirement of law: 2008/57/EC technical specification for interoperability relating to the ‘rolling stock – locomotives and passenger rolling stock’ subsystem (TSI LOC&PAS)

- Needed measures for fire prevention and protection (EN 45545)

- Material Tests EN 45545-2

- Fire spreading protection EN 45545-3

- Test reports of ISO 17025 accredited test laboratories (e.g. DMT)

Approval by notificated body (NoBo) (e.g. TÜV NORD)

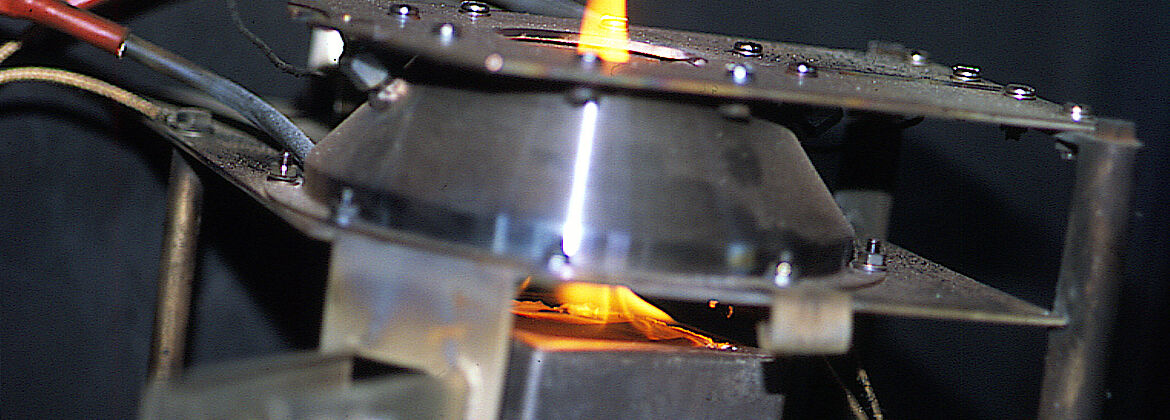

Our test lab for rolling stock (locomotives, carriages, wagons, and other service vehicles used on a railroad) is accredited by the German Accreditation Authority DAkkS. Based on this we are carrying out fire tests according to (DIN) EN 45545 and DIN 5510-2.

The fire performance of materials and components depends on their inherent characteristics. Further dependencies result from the application site of the material or component in use within the construction, the exposed surface or the relative mass and thickness of the material.

Products are categorized and distinguished in subgroups as follows:

- Application in accessible or non-accessible areas (staff areas, …)

- Concerning its general area of use (inside or outside)

- Regarding its special case of use (furniture, electrotechnical components, mechanical components, …)

The design and operation categories according to (DIN) EN 45545-1 are used to determine the required hazard level (HL) for a certain product. The hazard level represents the minimum of the required fire performance levels of a product in its case of use.

Based on the properties mentioned above a certain product has to fulfil one of 26 requirement sets (R1 – R26) specified in (DIN) EN 45545-2. Dependent of the design of the vehicle and the infrastructure it’s surrounded by (tunnels, …) different fire performance levels have to be fulfilled.

The combination of a requirement set and required hazard level lead to one or more fire tests with their related assessment criterions and limits which are necessary to be fulfilled by the product.

The test methods, which are part of several requirement sets, are:

- Reaction to fire tests – Spread of flame (ISO 5658-2)

- Determination of the optical density by a single chamber test (EN ISO 5659-2)

- Reaction to fire tests – Heat release rate (cone calorimeter method) (ISO 5660-1)

- Reaction to fire tests for floorings – Determination of the burning behaviour using a radiant heat source (EN ISO 9239-1)

- Determination of burning behaviour by oxygen index (EN ISO 4589-2)

- Analysis of gaseous effluents (NF X 70-100-1/-2)

- Determination of toxic gases from railway products (EN 45545-2, Annex C)

- Ignitability of products subjected to direct impingement of flame (EN ISO 11925-2)

- Textiles – Assessment of the ignitability of bedding items (EN ISO 12952-2)

- Fire test method for seating (EN 45545-2, Annex B)

Further fire technical tests:

- Fire resistance requirements for fire barriers (EN 45545-3)

- Fire resistance tests for carriage transitions (UIC 564-2)

- Fire material tests (UIC 564-2)

- Furniture – Assessment of the ignitability of upholstered furniture – smouldering cigarette (EN 1021-1)

- Furniture – Assessment of the ignitability of upholstered furniture – ignition source match flame equivalent (EN 1021-2)

- Assessment of the ignitability of mattresses and upholstered bed bases – smouldering cigarette (EN 597-1)

- Assessment of the ignitability of mattresses and upholstered bed – match flame equivalent (EN 597-2)

- Fire resistance tests (EN 1363-1, EN 1364-1, EN 1366-3, …)

Contact

Downloads

Part 1 (EN 45545)

contains the basic definitions and the general rules that divide rail vehicles into different design and operation categories as well as objectives for fire protection.

| Operation Category 1: | Vehicles for operation on infrastructure where railway vehicles may be stopped with minimum delay, and where a safe area can always be reached immediately. |

| Operation Category 2: | Vehicles for operation on underground sections, tunnels and/or elevated structures, with side evacuation available and where there are stations or rescue stations that offer a place of safety to passengers, reachable within a short running time |

| Operation Category 3: | Vehicles for operation on underground sections, tunnels and/or elevated structures, with side evacuation available and where there are stations or rescue stations that offer a place of safety to passengers, reachable within a long running time |

| Operation Category 4: | Vehicles for operation on underground sections, tunnels and/or elevated structures, without side evacuation available and where there are stations or rescue stations that offer a place of safety to passengers, reachable within a short running time. |

ISO 5658-2 SPREAD OF FLAME

ISO 5660-1 CONE CALORIMETER

ISO 5659-2 - DIN EN 45545-2-2016 - smoke and toxicity

Railway vehicles are additionally classified under the following Design Categories:

- A: vehicles forming part of an automatic train, having no emergency trained staff on board

- D: double decked vehicles

- S: sleeping and couchette vehicles

- N: all other vehicles (standard vehicles)

Freight wagons are excluded from this standard. They are, however, dealt with in the TSI and also have to meet the fire protection requirements of EN 45545-2.

Part 2 (EN 45545-2)

Fire Tests according to DIN EN 45545-2 (CEN TS 45545 Part 2)

This part specifies the reaction to fire performance requirements for materials and products used on railway vehicles as defined in EN 45545-1. For each hazard level, this part specifies the test methods, test conditions and reaction to fire performance requirements. The requirements for listed products are divided into 26 requirement sets (R1 - R26).

The respective test methods are, for example:

- Reaction to fire tests - Spread of flame (ISO 5658-2)

- Determination of the optical density by a single chamber test (EN ISO 5659-2)

- Reaction to fire tests - Heat release rate (cone calorimeter method) (ISO 5660-1)

- Reaction to fire tests for floorings - Determination of the burning behaviour using a radiant heat source (EN ISO 9239-1)

- Determination of burning behaviour by oxygen index (EN ISO 4589-2)

- Analysis of gaseous effluents (NF X 70- 100-1/-2)

- Determination of toxic gases trom railway products (EN 45545-2, Annex C)

- lgnitability of products subjected to direct impingement of flame (EN ISO 11925-2)

- Textiles - Assessment of the ignitability of bedding items (EN ISO 12952-2)

Products classified as A1 according to EN 13501-1 and products described in commission decision 96/603/EC (as amended) comply with the highest level of reaction to fire performance and therefore need no further testing.

Part 3 (EN 45545-3)

This part specifies the fire resistance requirements and testing methods for fire barriers for railway vehicles.

The objective of the measures and requirements, specified in this part of (DIN) EN 45545, is to protect passengers and staff in railway vehicles in the event of a developing fire on board.

The fire resistance tests are conducted at our site in Lathen:

- EN 1363-1: 1999, Fire resistance tests - Part 1: General requirements

- EN 1363-2:1999, Fire resistance tests - Part 2: Alternative and additonal procedures

- EN 1364-1:1999, Fire resistance tests for non-loadbearing elements - Part 1: Walls

- EN 1364-2: Fire resistance tests for non-loadbearing elements - Part 2: Ceilings

- EN 1634-1, Fire resistance and smoke control tests for door, shutter and openable window assemblies and elements of building Hardware - Part 1: Fire resistance tests for doors, shutters and openable windows

- EN 13501-1:2010 Fire classification of construction products and building elements — Part 1: Classification using data from reaction to fire tests

- EN 13501-2, Fire classification of construction products and building elements — Part 2: Classification using data from fire resistance tests, excluding ventilation services

- EN 45545-5, Railway applications — Fire protection on railway vehicles — Part 5: Fire safety requirements for electrical equipment including that of trolley buses, track guided buses and magnetic levitation vehicles

Fire barriers are tested according to different criteria:

- E - Integrity means that there is no flaming on the unexposed side and that there are no cracks or openings

- EW - Integrity + Radiation means that in addition to the E criterion also the limitation of heat transmission is important

- EI - Integrity + Insulation means that in addition to the E criterion and the limitation of heat transmission also the temperature on the unexposed side is important

Part 4 (EN 45545-4)

This part specifies fire safety requirements for railway vehicle design.

Part 5 (EN 45545-5)

This part specifies the fire safety requirements for electrical equipment including that of trolley buses, track guided buses and magnetic leviation vehicles.

Part 6 (EN 45545-6)

This part specifies requirements for fire detection, alarm systems, equipment shutdown, information and communication systems, emergency lighting, emergency brake systems and fire fighting systems.

Part 7 (EN 45545-7)

This part specifies requirements for flammable liquids and liquefied petroleum gas installations, e. g. for traction, auxiliary power units, heating or cooking.

Fire Tests according to DIN 5510-2

Classes S1-S5; SR1-SR2; ST1-ST2

This standard applies to rail vehicles within the purview of the German Railway Construction and Operating Ordinance (EBO), the Construction and Operating Ordinance for Narrow-Gauge Railways (ESBO), the Magnetic Levitation Train Construction and Operating Ordinance (MbBO) and the Construction and Operating Ordinance for Streetcars (BOStrab). The purpose of the standard is to establish classifications for fire behaviour and the side-effects of combustion for materials and components used in building the vehicles. Also to be specified are the testing procedures required for this purpose, requirements as to fire behaviour and combustion side effects, and requirements associated with fire prevention.

The objective of testing as per DIN 5510-2:2009-05, in conjunction with DIN 53438 (S1) and DIN 54837, is to determine the fire behaviour of materials used in rail vehicles when exposed to the flame of a gas burner. The findings are used for classification as per flammability, smoke generation and drip properties.

The test procedure is described in DIN 53438 and/or DIN 54837 while DIN 5510-2 details the requirements, test procedures and classifications.

S1

Testing to determine the flammability class (S1) is conducted as per the DIN 53438-1 to DIN 53438-3 standards. At least 5 small parts are used as specimens (see DIN 5510-2, Paragraph 5.3 b); alternately, specimens as per DIN 53438-1 to DIN 53438-3 may be used. The parts are mounted in their installed orientation while being exposed to the flame wherein the most critical exposure configuration for the installed small component will be selected. The flame will be directed at the surface, in so far as the edges are not covered. If the edges are exposed, then the flame will be directed at these edges. The test is deemed to have been passed if the flames supported by the small component do not exceed a height of 15 cm, measured from the point at which the burner’s flame impinges upon the part to the tip of the flame.

DIN 5510-2

Proof of suitability for use in regard to fire protection is generally to be demonstrated by way of tests carried out on original-equipment seats with the backrest and all the original-equipment components installed. The purpose of testing as per DIN 5510-2 is to determine the ignition and burning properties of seats and bench-type seats in rail vehicles when exposed to a burning paper cushion.

The following requirements are to be satisfied during testing as per Section 4.2.5.3 in order to demonstrate suitability: the height of the flame, above the highest point on the seat surface, may not exceed 100 cm. In none of the seats may the leading edge of the flames reach the side edges of the seat. The flames shall have gone out after the 15th minute of testing, at the latest. To satisfy fire protection steps 2 to 4, no individual value in total smoke production (TSP) may exceed a value of 60 m². Supplementary requirements will be found in the current version of the standard.

S2 - S5

As regards flammability classes S2 to S5, testing is described in DIN 54837. Here again at least 5 specimens measuring 190 mm x 500 mm x product thickness will be required. Components such as head restraints, fold-away tables, arm rests, covers that (due to their shape or dimensions) do not permit removal of test specimens 190 mm x 500 mm in size are to be carried out either at original size or using a section of the component of a suitable shape. If it is not possible to assess the flammability for such parts at all, then the inspection can be made on flat models measuring 190 mm x 500 mm. Sections 500 mm long are to be used when testing profiled components such as window and door gaskets, braces, hoses, cover strips, tubing and the like. (Alternately, sections as per Table 5 in DIN 5510-2 may be used)

Testing smoke toxicity in the testing chamber according to DIN EN ISO 5659-2 (DIN 5510-2:2009-05)

Additional requirements in the DIN 5510-2 standard

Smoke toxicity is tested for vehicles in fire protection steps 2 to 4 in accordance with Annexes C and D of DIN 5510-2 (May 2009). Three test specimens measuring 75 mm square are used. The test specimens are to correspond to the final application. The thickness of the test specimens may, however, not exceed 25 mm. Thicker items are to be reduced, on the surface not to be exposed to the flame during testing, to an overall thickness of 25 mm. The test specimens, in a horizontal orientation, are to be subjected to thermal radiation at a level of 25 kW/m². The smoke released will be collected and toxicity analysis will follow twice, i.e. after 4 and 8 minutes of exposure.

Smoke toxicity is then evaluated on the basis of the fractional effective dose (FED). Used as the basis here is a reference volume of 150 m³ for the vehicle.

Vehicle components satisfy the requirements of the various fire protection states if FED(tpermissible) is equal to or less than 1.