IMO FTP Codes

DMT carries out the following tests of materials and components for use on ships and yachts according to IMO-Resolution MSC.307(88) - „International Code for Application of Fire Test Procedures, 2010“ (2010 FTP Code) at the fire test sites Dortmund and Lathen.

- Material testing on Non-Combustibility according to IMO 2010 FTP Code Part 1, IMO-Resolution MSC.307(88) - ISO1182

- Material testing on smoke density and toxicity according to IMO 2010 FTP Code Part 2, IMO-Resolution MSC.307(88) - ISO 5659-2

- Fire test procedure for vertical and horizontal divisions according to IMO 2010 FTP Code Part 3, IMO-Resolution MSC.307(88)

- Test for fire door control systems according to IMO 2010 FTP Code Part 4, IMO-Resolution MSC.307(88)

- Fire tests for surface flammability for linings, coatings and floor covers according to IMO 2010 FTP Code Part 5, IMO-Resolution MSC.307(88)

- Fire test for vertically supported textiles and films according to IMO 2010 FTP Code Part 7, IMO-Resolution MSC.307(88)

- Fire tests for upholstered furniture according to IMO 2010 FTP Code Part 8, IMO-Resolution MSC.307(88)

- Fire tests for bedding components according to IMO 2010 FTP Code Part 9, IMO-Resolution MSC.307(88)

- Fire test procedures for heat release, smoke production and mass loss rate for materials according to IMO 2010 FTP Code Part 10, Appendix 2 IMO-Resolution MSC.307(88)

International Code for Application of Fire Test Procedures

| FTP Code | Test | Directive | Testing Procedure |

| Part 1 | Testing on Non-Combustibility | MSC.307(88) | ISO 1187 |

| Part 2 | Testing on Smoke Density and Toxicity | MSC.307(88) | ISO 5659-2 |

| Part 3 | Testing of Vertical and Horizontal Divisions, Classes A, B and F | MSC.307(88) | ISO 834-1 |

| Part 4 | Testing of fire door control systems | MSC.307(88) | - |

| Part 5 | Testing of Surface Flammability for Linings, Coatings and Floor Covers | MSC.307(88) | ISO 5658-2 |

| Part 7 | Testing of Vertically Supported Textiles and Films | MSC.307(88) | ISO 6940/41,EN 1101/02 |

| Part 8 | Testing of Upholstered Furniture | MSC.307(88) | BS 5852-1, ISO 8191-1/2, EN 1021-1/-2 |

| Part 9 | Testing of Bedding Components | MSC.307(88) | EN 597-1/-2 |

| Part 10, Appendix 2 | Testing of Heat Release, Smoke Production and Mass Loss Rate | MSC.307(88) | ISO 5660 |

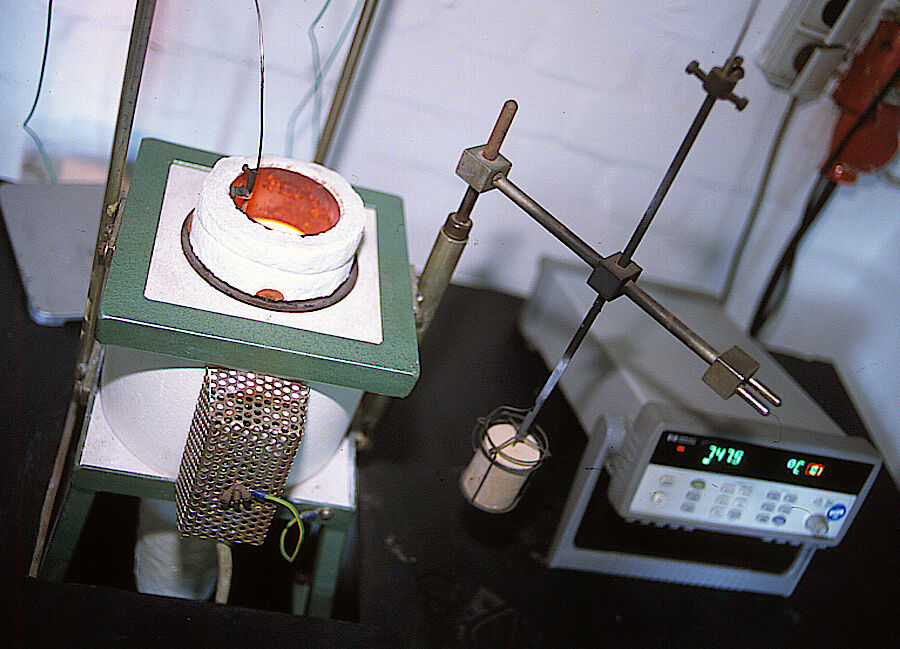

Non-Combustibility

Many materials used for construction of divisions aboard a ship - except for adhesives - must comply with the test criterion of non-combustibility according to IMO regulations.

The conduction of non-combustibility tests and classification of tested materials is carried out according to the „International Code for Application of Fire Test Procedures (FTPC)":

- IMO 2010 FTP Code Teil1, IMO-Resolution MSC.307(88)

Testing Procedure

Cylindrical specimen (H = 50 mm, Ø = 45 mm) are heated up to 750°Celsius (±5°C) within an electrically heated furnace according to DIN EN ISO 1182. During this test two thermocouples measure the occurring temperature. One thermocouple (furnace thermocouple) measures the temperature inside of the furnace. The second thermocouple (specimen surface thermocouple) measures the temperature at the surface of the specimen. During the test the instant of time as well as the duration of occurrence of any sustained flaming are recorded.

Furthermore moisture content and organic content of specimens are determined.

Each specimen is also weighed before and after the test in order to calculate the mass loss of the specimen after the test.

Testing Criteria

According to IMO 2010 FTPC Part 1 the sample material is classified as "non-combustible" if the following four criteria are satisfied:

- Average furnace temperature rise not exceeding 30°C (determined accord. to paragraph 7.5.3 of DIN EN ISO 1182:2010)

- Average specimen surface temperature rise not exceeding 30°C (determined accord. to paragraph 7.5.3 of DIN EN ISO 1182:2010)

- Average Duration of sustained flaming less than10 seconds (determined accord. to paragraph 7.5.2 of DIN EN ISO 1182:2010)

- Average mass loss less than 50% (determined accord. to paragraph 7.5.1 of DIN EN ISO 1182:2010)

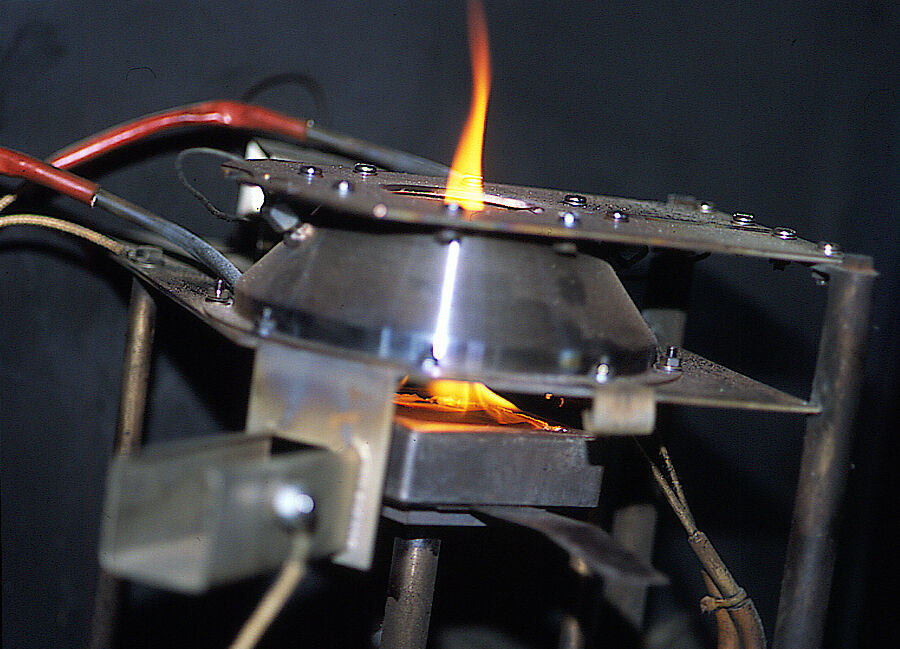

Smoke Density and Toxicity

For coating materials used aboard ships, e.g. paintings, adhesives, laminates, carpeting etc. which are applied on bulkheads, linings, decks, ceilings and floors the criteria for smoke density and toxicity have to be satisfied – if it is required.

The test procedure and the classification of the tested material is conducted according to the „International Code for Application of Fire Test Procedures (FTPC)":

- IMO 2010 FTP Code Part 2, IMO-Resolution MSC.307(88)

Testing Procedure

In a test chamber according to DIN EN ISO 5659-2 square shaped specimens are irradiated with 25 kW/m² without pilot flame, 25 kW/m² with pilot flame and with 50 kW/m² without pilot flame. The generated smoke is captured within the test chamber. After obtaining the maximum smoke density, the samples for the assessment of toxicity are extracted from the gases and analyzed by a FTIR spectrometer.

Testing Criteria for Smoke Density

- Surface coatings for bulkheads, walls, linings etc. must not exceed a value for Dm of 200 in any test condition.

- Primary deck coverings shall not exceed a value for Dm of 400 in any test condition.

- Floor coverings must not exceed a value of 500 for Dm in any test condition.

- Plastic pipes and electrical cables shall not exceed a value of 400 for Dm in any test condition.

Testing Criteria for Toxicity

| Gas Constituent | Limit |

| CO | 1450ppm |

| HCI | 600ppm |

| HF | 600ppm |

| HBr | 600ppm |

| HCN | 140ppm |

| NOx | 350ppm |

| SO2 | 120ppm |

| SO2 (for floor coverings) | 200ppm |

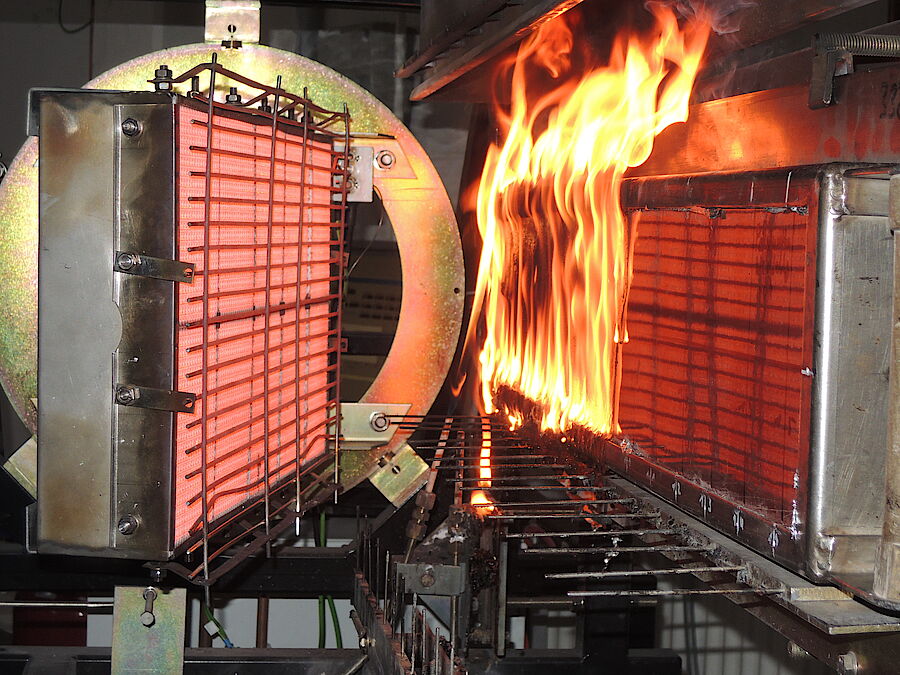

Vertical and Horizontal Divisions

On board of ships horizontal and vertical divisions like ceilings, walls, windows and doors must be fire-resisting.

The fire tests on divisions of types A, B and F are conducted according to the „International Code for Application of Fire Test Procedures (FTPC)”:

- IMO 2010 FTP Code Part 3, IMO-Resolution MSC.307(88)

Testing Procedure

For the fire resistance test the standard time-temperature curve according to ISO 834-1 is reproduced within a special furnace.

The testing duration is 30 minutes or 60 minutes.The divisions must withstand the fire without any flame formation or emission of hot gases on the unexposed side. Further the temperature rise on unexposed surface of ceilings, walls, floors and doors must not exceed 180°C resp. 225°C depending on classification criterion. By the „cotton-wool pad test" the integrity of a construction (e.g. fire damper) is examined. If there is a flaming or glowing of the cotton-wool pad, this test is failed.

Classification

This test serves to assess whether the tested divisions meet the specified criteria within the test duration.

“A” class divisions (test duration 60 minutes)

| Class | Average Temperature Rise ≤ 140°C for | Max. Temperature Rise ≤ 180°C for | Integrity kept for |

| A-60 | 60 minutes | 60 minutes | 60 minutes |

| A-30 | 30 minutes | 30 minutes | 60 minutes |

| A-15 | 15 minutes | 15 minutes | 60 minutes |

| A-0 | not applicable | not applicable | 60 minutes |

"B" and "F" class divisions (test duration 30 minutes)

| Class | Average Temperature Rise ≤ 140°C for | Max. Temperature Rise ≤ 225°C for | Integrity kept for |

| B-15 | 15 minutes | 15 minutes | 30 minutes |

| B-0 | not applicable | not applicable | 30 minutes |

| F-15 | 15 minutes | 15 minutes | 30 minutes |

| F-0 | not applicable | not applicable | 30 minutes |

Surface Flammability

Any coating materials used aboard ships, e.g. paintings, adhesives, laminates, carpeting etc. which are applied on bulkheads, linings, decks, ceilings and floors have to be tested for surface flammability.

The test procedure for surface flammability and the classification of the tested material is conducted according to the „International Code for Application of Fire Test Procedures (FTPC)”:

- IMO 2010 FTP Code Part 5, IMO-Resolution MSC.307(88)

Test Procedure

The materials to be tested are exposed to a specified irradiance level which is generated by a heat radiator. During the test the time of ignition, the flame-spread characteristics, extinguishing of flames and the heat release are measured and recorded.

From these determined data the following measuring results are calculated:

- CFE:Critical fluxat extinguishment

- Qsb: Heatforsustainedburning

- Qt: Total heatrelease

- Qp: Peak heatreleaserate

Classification

This test is used to determine if the tested coating material complies to the surface flammability criteria required for low-flame spread according to IMO 2010 FTPC part 5. In addition these materials must not generate extraordinary quantities of smoke nor release toxic gases in event of a fire.

This has to be verified according to IMO 2010 FTPC Part 2. Surface materials and primary deck coverings with a total heat release of maximum (Qt) ≤ 0,2 MJ and a maximum peak heat release rate of (Qp) ≤ 1,0 kW are excluded from this requirement.

| Surface flammability criteria for | CFE [kW/m²] | Qsb [MJ/m²] | Qt [MJ] | Qp [kW] |

| Bulkhead, wall and ceiling linings | ≥ 20,0 | ≥ 1,5 | ≤ 0,7 | ≤ 4,0 |

| Primary deck coverings | ≥ 7,0 | ≥ 0,25 | ≤ 2,0 | ≤ 10,0 |

| Floor coverings | ≥ 7,0 | ≥ 0,25 | ≤ 2,0 | ≤ 10,0 |

Vertically Supported Textiles and Films

The fire tests for curtains, draperies and other vertically supported textiles for which a fire resistance class is required are conducted according to the „International Code for Application of Fire Test Procedures (FTPC)":

- IMO 2010 FTP Code Part 7, IMO-Resolution MSC.307(88)

Test Procedure

At this test procedure the mode of flame application is evaluated by pre-tests.

The flame is applied to the surface of the material for 5 respectively 15 seconds. If no sustained ignition occurs the flame is applied to the edge of the material for 5 respectively 15 seconds.

As the mode of flame application delivering the worst test results is determined, 5 specimens in warp direction and 5 specimens in weft direction are tested with this test setup.

To investigate if burning drops of the specimen are capable of igniting combustible materials on the base of the test apparatus, cotton wool with a thickness of 10 mm shall be laid over the base plate.

Classification

Products which show any of the following characteristics shall be considered unsuitable for use as curtains, draperies or free-hanging fabric:

- An after-flame time greater than 5 seconds for any of the specimens.

- Burn through to any edge of any of the specimens.

- Ignition of cotton wool below the specimen.

- An average char length in excess of 150 mm observed in any of the batches of five specimens.

- Occurence of a surface flash propagating more than 100 mm from the point of ignition with or without charring of the base fabric.

Upholstered Furniture

On board of ships seats, sofas, armchairs etc. have to have qualities of resistance against propagation of flame.

The test procedure for upholstered furniture and the classification of the tested material is conducted according to the „International Code for Application of Fire Test Procedures (FTPC)":

- IMO 2010 FTP Code Part 8, IMO-Resolution MSC.307(88)

Test Procedure

It is tested wether a progressive smouldering or open flames occur at covers and filling. A smouldering cigarette is used as smouldering ignition source. A lighted match or a flickering candle is simulated by a propane gas flame. The ignition source is placed at the joint between the seat and back of the specimen.

Classification

Covers and fillings of seat and lying surfaces are recognized as resistant against propagation of flame if:

- no progressive smouldering and

- no open flames can be observed.

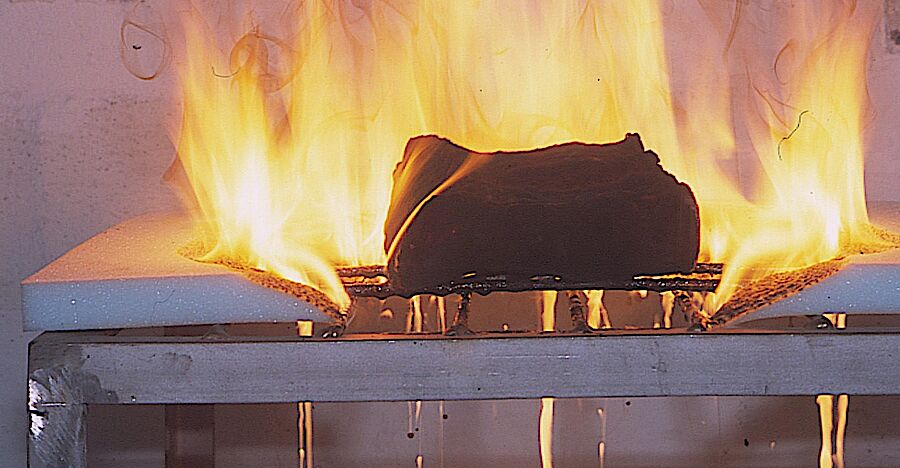

Bedding Components

Bedding Components

On board of ships only mattresses, blankets and pillows may be used which have qualities of resistance to the ignition and propagation of flame - as well as bedspreads and quilts. The test procedure for bedding components and the classification of the tested material is conducted according to the „International Code for Application of Fire Test Procedures (FTPC)":

- IMO 2010 FTP Code Part 9, IMO-Resolution MSC.307(88)

Test Procedure

It is tested whether a progressive smoulderingor open flames occur. A smouldering cigarette covered with a cotton wool pad is used as smouldering ignition source, which shall simulate falling asleep with a burning cigarette. A lighted match or a flickering candle is simulated by a propane gas flame which is placed on top of the specimen.

Classification

Bedding components are classified as not readily ignitable if they:

- withstand the fire test for 60 minutes and

- show no progressive smouldering ignition or flaming ignition.

Heat Release, Smoke Production and Mass Loss Rate for Materials

Materials used for furniture and other components on board of high speed vessels shall be fire-restricting material. The test procedure and the classification of the tested material is conducted according to the „International Code for Application of Fire Test Procedures (FTPC)":

- IMO 2010 FTP Code Part 10, Appendix 2 IMO-Resolution MSC.307(88)

Test Procedure

The specimens are exposed to controlled levels of irradiance in horizontal orientation. The heat release rate is determined by measurement of the oxygen consumption. In addition the time to ignition and the smoke production rate are recorded.

Classification

Materials used for furniture and other components are qualified as „fire-restricting material" if the following four criteria are fulfilled:

- The time to ignition (TIG) is greater than 20 seconds,

- The maximum 30-second sliding average heat release rate (HRR30,max) does not exceed 60 kW/m²,

- The total heat release (THR) does not exceed 20 MJ/m² and

- The time average smoke production rate (SPRavg) does not exceed 0.005 m²/s.