Cooling, Air Conditioning and Heating Technology

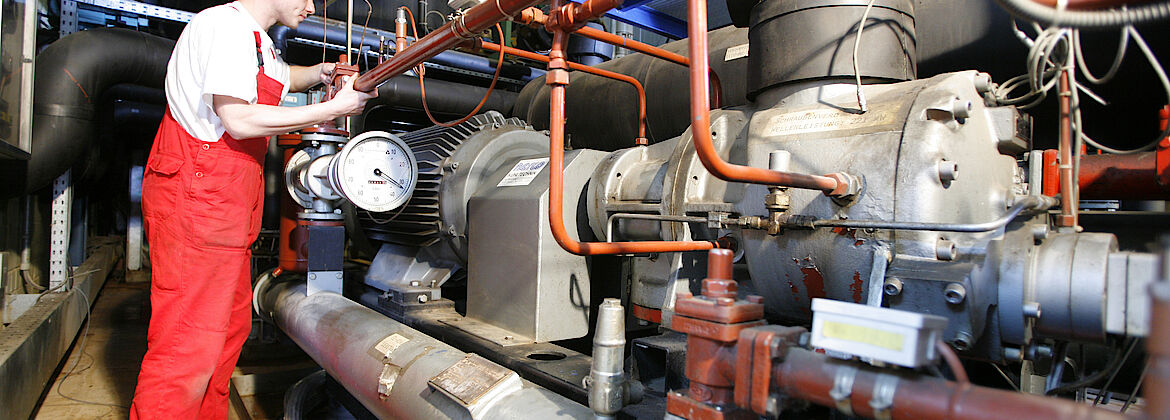

In our test center for refrigeration, air-conditioning and heat technology, we carry out normative and nonstandard performance measurements for manufacturers and operators of machines and components for refrigeration and heating technology. As an independent testing laboratory, we are active in several certification programs for EUROVENT-CERTIFICATION, Paris, for the Institute for Air Conditioning, Heating and Refrigeration (AHRI) und for the INSTITUTE cooling Tower (CTI).

The tests of refrigeration machines, heat pumps, air coolers, condensers, recoolers, heat exchangers (air / liquid and liquid / liquid), air conditioning systems, cooling towers and other air-conditioning systems can be tested on our test stand in Essen or at external locations, e.g. your manufacturing facility or the place of assembly.

Reliable determination of energy balance

Due to climate change, low-emission solutions in refrigeration, air-conditioning and ventilation technology are becoming increasingly important within our industry.

Research and development of a wide range of components, the design and planning of building technology, as well as the operation by the end consumer are placing growing demands on the implementation of projects.

We are an independent testing laboratory and can determine reliable data for you on our multifunctional test stand in Essen.

You can't come to us? We also test worldwide thanks to our mobile solutions; at your site.

Thus we contribute to a successful implementation of your Projects supportive and sustainable.

“Cool” Testing - Testing laboratory for refrigeration and climate

Reliable data from an independent testing body

Are you looking for a test rig to complement your own testing facilities, on which the performance of your refrigeration machines or individual components can be determined by an independent body. The results of our tests can stand up to legal examination and are therefore of particular importance in connection with consequential product liability.

Test rig performance

Using our multi-functional test rig, we ascertain the actual efficiency of systems and components in refrigeration and air conditioning technology under design conditions, starting from water and air-cooled refrigeration machines, heat pumps and evaporators or condensers, air coolers and liquid heat exchangers, right through to cooling towers, re-coolers and all forms of air conditioning devices.

In particular, air conditioning devices with heat recovery (plate heat exchangers, heat wheels etc.) can also be measured as a second air preparation system is available.

Completely irrespective of what you place on our test rig - we demonstrate the respective performance precisely, whereby varying refrigerants can be used.

Tests are carried out by

- Water and air-cooled chillers

- Water- and air-cooled heat pumps

- Air cooler and liquid heat exchanger

- Cooling towers, hybrid coolers and recoolers

- Air conditioners and precision air conditioners

- Heat recovery systems

- Ventilation and domestic ventilation units

- Ventilators

Tests over a broad performance range that conform to standards

We carry out tests in a performance range of 5 to approximately 2,500 kW in accordance with your instructions or with relevant standards. Depending on requirements, the water temperature can be set from 1.5 °C to 60 °C. Given the use of brine, the tests can also run at minus temperatures. The air flow can be conditioned; in this respect, temperatures of between +2 °C and +60 °C are possible. The air humidity can be set over a broad range. The maximum air volume flow available is 70 m³/s (=252,000 m³/h).

Naturally, we are also flexible when it comes to the electrical connection ratings. Amongst other things, the frequency required for the US market, UAE, China and India is also available.

Development-accompanying tests

The capacities of your own testing facilities are not sufficient for comprehensive development-accompanying examinations or are not sufficiently dimensioned in terms of performance. Our test rig is also ideally suited for these tasks, particularly as a high degree of stability of the air and water-side inlet conditions is assured even during long-time tests. Furthermore, our testing work also provides a secure basis for improving the reliability of performance characteristics and their specific calculation programs. In this way, we make a decisive contribution to your quality assurance. Naturally, the cost factor also plays an important role: if you have the capacity tests carried out by DMT, you can dispense fully with an own, expensive test rig under certain circumstances or have your test programs carried out in performance ranges that you yourselves cannot realise. There is no need for an expensive extension of the test rig.

Complete recognition thanks to long years of experience

Our experts have decades of experience in performance examinations and tests in the field of refrigeration and air conditioning. The test rig for refrigeration, air conditioning and heat technology is accredited as per DIN EN ISO/IEC 17025. It is not least for this reason that we are recognised by EUROVENT Certification as a testing laboratory.

Additional services

Apart from the actual testing work in the field of refrigeration and air conditioning, we can also offer you a host of additional services:

- Acoustic measurements as per ISO 3744, ISO 9614

- Testing of ventilation and air conditioning devices for conformity with VDI 6022

- Hygiene inspections

- Hygiene training

- Independent expert reports for refrigeration and air conditioning technology

- Carrying out of complete, on-site performance measurements on installed devices or on the manufacturer’s premises

Technical data of the test rig

Water side:

- Flow rate on cold water side up to 500 m³/h

- Flow rate on cooling water side up to 500 m³/h

- Temperatures of 1.8 to 60 °C (without glycol), (with glycol also very low temperatures)

Air sides:

1st air side: conditioned air flow rate up to 60 m³/s

2nd air side: conditioned air flow rate up to 10 m³/s

Temperatures from –10 to 60 °C

Relative air humidity at 32 °C up to 95 %

Max. performances of the items tested:

- Water-cooled chiller up to approx. 2,500 kW

- Air-cooled chiller and heat pumps up to approx. 600 kW

- Evaporators (water) up to approx. 1,000 kW

- Evaporators (air) up to approx. 600 kW

- Condenser (water) up to approx. 1,100 kW

- Condenser (air) up to approx. 700 kW

- Cooling towers with conditioned air up to approx. 800 kW (considerably higher performances possible with conditioned water)

- Dry-coolers up to approx. 600 kW

- Heat exchangers (liquid/liquid) up to approx. 1,000 kW

Data of the test hall:

- Usable hall length 18 m, width 5.5 m

- Maximum height of crane hook 7.9 m

- Carrying capacity of the crane 80 kN

- Admissible floor load 35 kN/m²

- Inner dimensions of the climatic chamber (L x H x W) approx. 10 x 3.6 x 5 m

- Electrical connection rating (at 50 Hz) 400 V / 270 kW

- Additional connection ratings, e.g. 500 V, 60 Hz (for the US market), or higher connection ratings can be provided on request

The most important standards

- EN 14511-1:2018-05

Air conditioners, liquid chillers and heat pumps for room heating and cooling and process coolers with electrically driven compressors. - EN 14825:2016

Air conditioners, liquid chilling packages and heat pumps, with electrically driven compressors, for space heating and cooling - Testing and rating at part load conditions and calculation of seasonal performance; German version EN 14825:2016 - AHRI Standard 551/591 (SI) & 550/590 (IP):2018

Performance Rating of Water-chilling and Heat Pump Water-heating Packages Using the Vapor Compression Cycle - ANSI/AHRI Standard 400:2015

Standard for Liquid-To-Liquid Heat Exchangers - EN 13053:2017-06

Ventilation of buildings -Central air handling units -Performance characteristics for units, components and assemblies - CTI STD-201:2001

Standard for Thermal Performance Certification of Evaporative Heat Rejection Equipment - CTI ATC-105:2000

Acceptance Test Code for Water Cooling Towers - CTI STD-146:2008

Standard for Liquid Flow Measurement - EN 1048:2014-11

Heat exchangers - Air cooled liquid coolers ('dry coolers') - Test procedures for establishing the performance; - EN 13741:2004-05

Thermal performance acceptance testing of mechanical draught series wet cooling towers; - EN ISO 9614-1:2009 -11

Acoustics - Determination of sound power levels of noise sources using sound intensity - Part 1: Measurement at discrete points (ISO 9614-1:1993) - EN 1216:2003 - 04

Heat exchangers - Forced circulation air-cooling and air-heating coils - Test procedure for establishing the performance - EN 1886:2007

Ventilation for buildings - Air handling units - Mechanical performance; - DIN EN 306:1997 - 07

Heat exchangers - Methods of measuring the parameters necessary for establishing the performance; - Eurovent Certita Certification RS-6/C/001A-2014

AIR CONDITIONERS Comfort air-cooled Air Conditioners and Air-to-air Heat Pumps - Eurovent Certita Certification RS 6/C/003-2019

CERTIFICATION of LIQUID CHILLING PACKAGES - Eurovent Certita Certification RS 6/C/003A-2019

CERTIFICATION of HEATING-ONLY HYDRONIC HEAT PUMPS - Eurovent Certita Certification RS 7/C/005 – 2016

Certification of FORCED CIRCULATION AIR COOLING AND HEATING COILS - Eurovent Certita Certification RS 9C/001 – 2014

EUROVENT RATING STANDARD for COOLING TOWERS - Eurovent Certita Certification RS/7/C/010-2018

CERTIFICATION of Liquid to liquid Plate Heat Exchangers - Eurovent Certita Certification RS/6/C/007-2019

CERTIFICATION of ROOFTOP

The results of our audits are legally reliable and of particular importance

in connection with product liability.

Contact

What does mean...

CTI

The INSTITUT cooling tower is a voluntary, non-profit, scientific Association for ensuring an acceptable minimum level of quality and performance of the Evaporative heat transfer systems and their components.

This is verified by establishing standard specifications, guidelines and certification programs.

The Cooling Tower Institute works in cooperation with Eurovent Certification.

DMT GmbH & Co. KG has been counting the INSTITUT cooling tower among its customers since 2016 and has the status Licensed CTI Thermal Testing Agencies & CTI Thermal Certification Testing Agencies.

AHRI

The Institute for Air Conditioning, Heating and Refrigeration Technology (AHRI) is the professional association, the manufacturer of heating, ventilation & air conditioning systems and cold water heaters in the global industry.

AHRI develops industry recognized performance standards and certification programs for industrial equipment, HVAC and water heating equipment.

DMT GmbH & Co. KG counts the Air-Conditioning, Heating and Refrigeration Institute to its customers since 2013.

Eurovent

Eurovent Certification certifies the performance data of the products for ventilation and refrigeration according to the European and international standards.

The aim is to strengthen customer confidence by harmonising the competitive conditions for all manufacturers and increasing the integrity and accuracy of industrial performance evaluations.

DMT GmbH & Co. KG has been Eurovent Certita Certification's customer since 1995.

![[Translate to English:] EN 14511](/fileadmin/_processed_/c/b/csm_kkwt02_d30c7fbcbe.jpg)